Who AM I ??

we are

Advanced Ceramic Solutions Provider

“We Focus on S-Sic and B4C ceramic products”

"You supply the design, we handle the production,

and deliver the finished product to your hands."

Here are the services we provide

Custom-engineered advanced ceramics to meet your specifications

You supply the design, we handle the production,

and deliver the finished product to your hands !

Why Choose Our Advanced Ceramic

Products?

Our pressureless sintered advanced ceramics are precision-engineered for reliability in extreme conditions.

With customizable shapes and sizes, we deliver high-performance solutions tailored to your needs.

In recognition of the organization's Quality Management System which complies with ISO 9001:2015

Our Advanced Ceramic Production Process

We possess end-to-end manufacturing capabilities from raw materials to final products.

High-Temp Sintering

Silicon Carbide (SSiC) Ceramic Components for High-Temperature Kilns

Product Features:

※High load.-bearing capacity,corrosion resistance

※Excellent oxidation resistance, maximum operation temperature up to 1650℃

※Long service life

Application Areas: Lithium battery field, High-temperature kilns

Silicon Carbide (SSiC) Ceramic Components for High-Temperature Kilns

Product Features:

※High load.-bearing capacity,corrosion resistance

※Excellent oxidation resistance, maximum operation temperature up to 1650℃

※Long service life

Application Areas: Lithium battery field, High-temperature kilns

文本

CNC Precision Finishing

Dry Pressing

Silicon Carbide (SSiC) Ceramic Components Solutions

Product Features:

※Excellent wearand corrosion resistance ※Adding Silicon carbon sulfide,has good self-lubricating property

※High thermal conductivity,low coefficient of thermal expansion ※Heat resistance and high mechanical strength

※High-temperature creep resistance and low friction

Application Areas: Mechanical industry,Chemical industry

Silicon Carbide (SSiC) Ceramic Semiconductor Components Products

Product Features:

※High purity, low content of metalimpurities ※Dense material, free of microcracks※Customized fabrication processes based on product requirements, and significant cost advantages.

Application Areas: The third-generation semiconductor chip manufacturing

Silicon Carbide (SSiC) Ceramic Armor Solutions

Product Features:

※ High hardness, strong impact resistance, superior bulletproof performance

※Low-density,lightweight

※ Reasonable price,comprehensive costadvantages

Application Areas:National defence, Military industry

Silicon Carbide (SSiC) Ceramic Heat Exchanger Component

Product Features:

※The comprehensive costis lower than graphite and metal

※High heatransfer efficiency, minimal heat exchange area required

※Corrosion-resistant, excellent mechanical properties, suitable for extreme high-temperature, high-pressure environments

※Ultra wear resistance andimpermeability, allow the medium to pass at high speed

Application Areas:Medical field, Chemicalindustry

Silicon Carbide (SSiC) Ceramic Components for High-Temperature Kilns

Product Features:

※High load.-bearing capacity,corrosion resistance

※Excellent oxidation resistance, maximum operation temperature up to 1650℃

※Long service life

Application Areas: Lithium battery field, High-temperature kilns

Boron carbide ( B₄C) Ceramic Components

Product Features:

※Exceptional resistance to abrasion, used in nozzles, bearings, and other wear-prone parts.

※Mohs hardness of approximately 9.3, ranking among the hardest known materials, second only to diamond and cubic boron nitride, making it ideal for grinding and cutting applications.

※Low density (2.52 g/cm³), lighter than aluminum, suitable for weight-sensitive military and aerospace components.

※Melting point up to 2450°C, maintaining stability in extreme heat

※Can function as a high-temperature thermoelectric material, converting heat into electricity.

Application Areas: Industrial Machining, Thermoelectric Materials

Business Partner

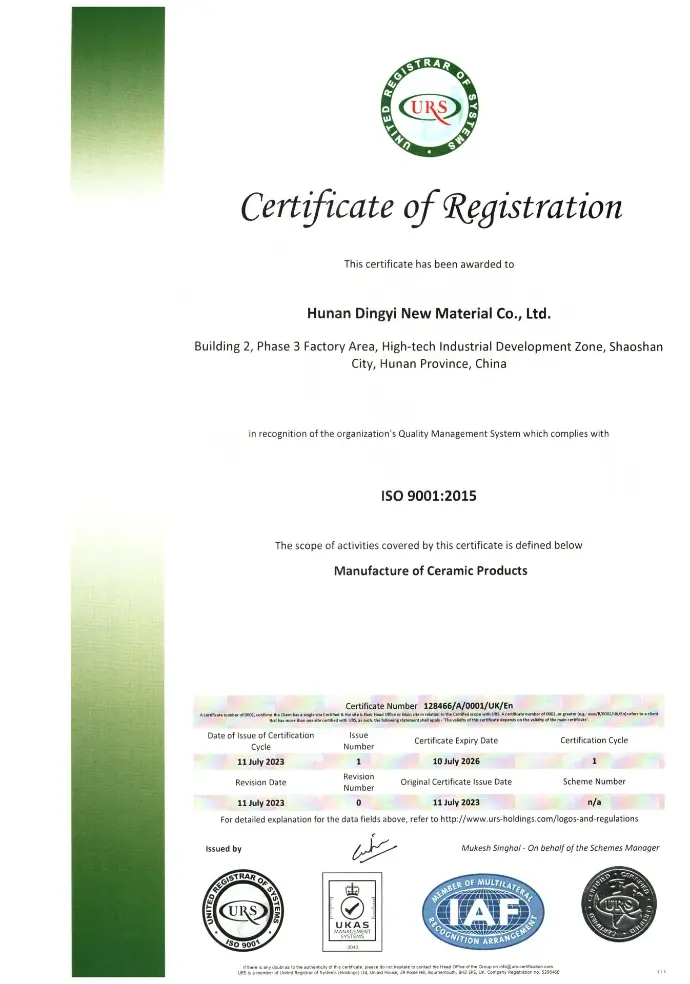

Certificate of Registration

in recognition of the organization's Quality Management System which complies with

ISO 9001:2015

The scope of activities covered by this certificate is defined below

Manufacture of Ceramic Products

[email protected]

+86 15813725662 (WhatsApp)

CHINA

Contact us

We look forward to hearing from you! Whether you have questions, feedback, or require support, our team is committed to serving you. Simply complete the form below, and we will respond to all inquiries within 24 hours. Thank you for contacting us!